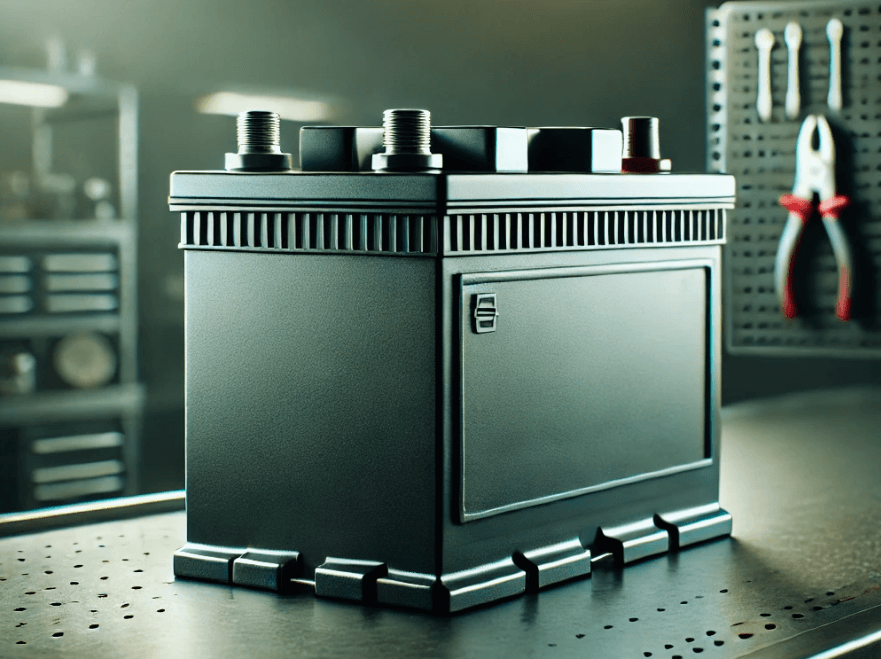

Are you tired of cramped space and clutter in your garage or workshop? Imagine transforming that cluttered corner into an organized haven for your automotive battery, while showing off your DIY skills.

Building your own custom automotive battery rack, if you like, not only helps streamline your space but also allows you to create a design that fits your specific needs, whether it’s for a car restoration project, racing endeavor, or simply to store extra batteries.

Today we’ll take you through the step-by-step process of building a strong and functional battery rack. Learn how to easily build a Custom Automotive Battery Rack.

Why Build Your Own Battery Rack?

Building your own automotive battery rack offers unparalleled customization, enabling you to tailor the design to your specific needs and vehicle setup.

Unlike typical store-bought options, a DIY battery rack can be engineered for optimal space utilization in terms of dimensions and weight distribution.

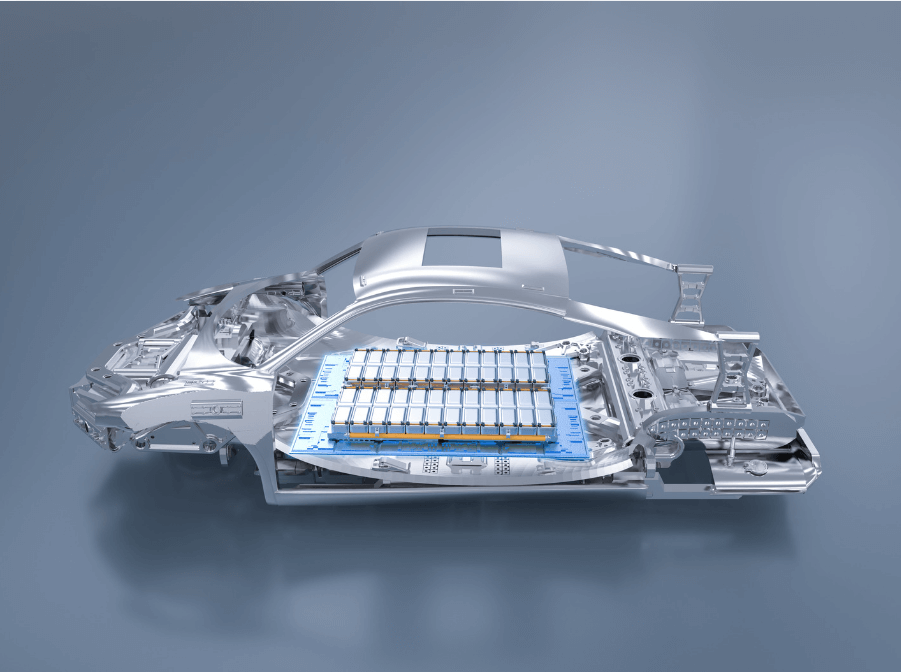

This is particularly advantageous for unique vehicle layouts or special applications such as racing or off-grid touring where battery performance is critical.

Building your own rack specifically allows for improved security features for your environment. By choosing corrosion-resistant materials and incorporating proper ventilation, you not only prolong the life of your battery but also reduce the fire risk common with improper storage.

A custom automotive battery rack provides a suitable solution for storing, protecting and optimizing battery systems in vehicles, especially in specialized applications such as electric vehicles (EV), off-road vehicles and fleet management. For example:

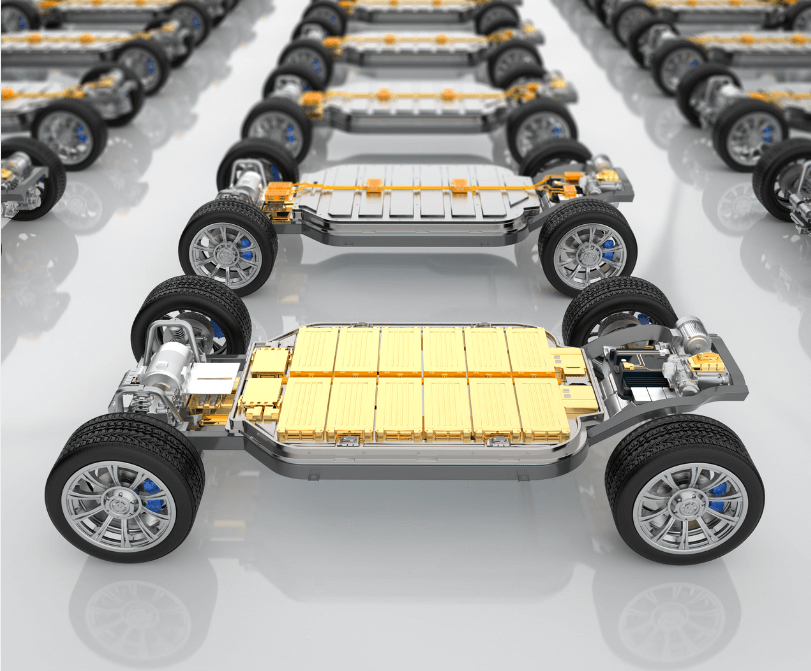

1. You can optimize space utilization: A custom battery rack can be designed to fit the exact dimensions and layout of the vehicle, ensuring efficient use of limited space. Moreover, they allow integration into unconventional or tight spaces (e.g., under the seat or in the trunk).

2. Improved battery safety: Provides a stable and secure mounting system to reduce vibration, movement or damage while driving. and

Reduces the risk of electrical faults due to loose or displaced batteries.

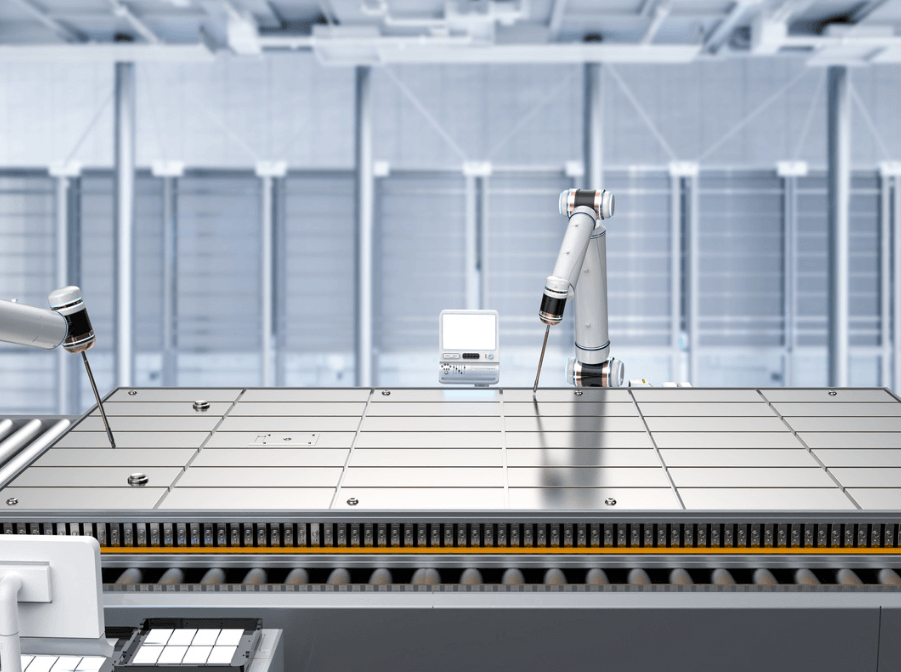

3. Improved cooling and ventilation: Custom racks can be designed with cooling channels, airflow systems or insulation to prevent overheating, which is important for high-performance or EV batteries that generate significant heat.

4. Improved organization and accessibility: Streamlines cable management, making it easier to connect, disconnect, or replace batteries. and

Easy access for maintenance or upgrades, saving time and effort.

5. Weight distribution and balance: Designed to position the battery in a way that improves the overall weight distribution of the vehicle, which improves handling and reduces stress on the suspension system.

6. Scalability for multiple batteries: Ideal for applications that require multiple batteries (e.g., EVs, RVs, or boats). And it enables expansion or modularity for additional power needs.

7. Safety standards compliance: Designed to meet industry safety regulations (e.g., fire prevention, shock absorption). Specifically prevents risks such as battery leakage, short circuit, or fire hazard.

8. Customizable for specific applications: Built to suit unique needs such as heavy-duty use, high-performance vehicles, or recreational setups.

Materials Needed for Your Project

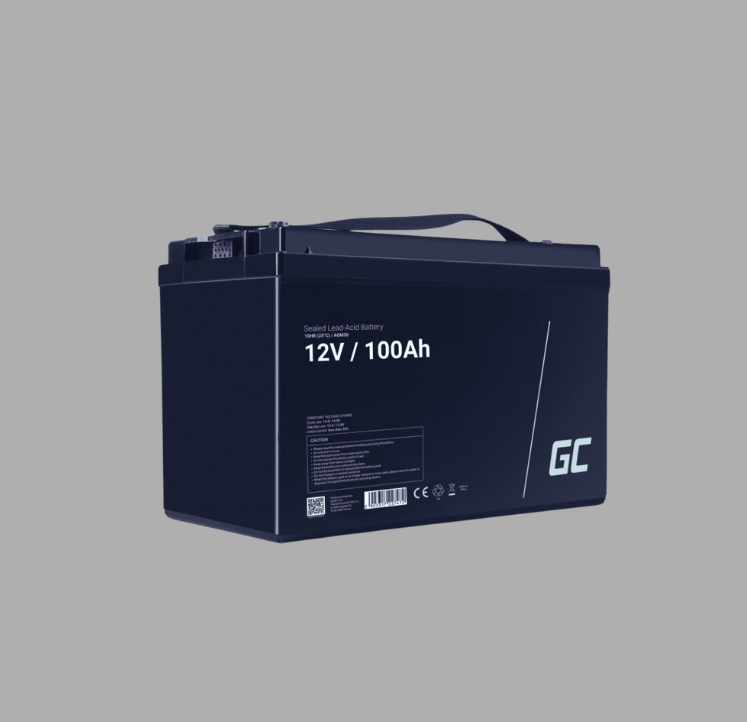

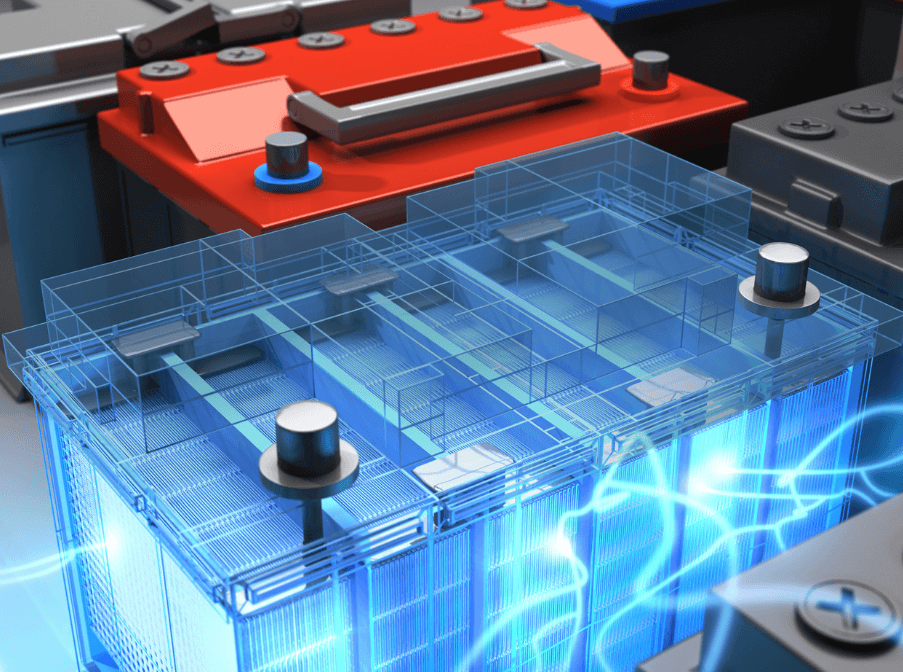

When starting an automotive battery rack construction project, choosing the right materials is critical for safety and longevity. Start with a strong yet lightweight metal, such as aluminum or steel, that can support the weight of multiple batteries while resisting corrosion and wear over time.

Additionally, consider using a high-density polyethylene (HDPE) sheet as a liner, this material not only provides additional protection against spills and leaks but also reduces vibration, protecting your battery from potential damage.

Also, don’t overlook the importance of insulation and padding materials. Rubber or foam padding can be incorporated into your design to provide cushioning and further protect your batteries from impact during transport or storage.

Bolts made from stainless steel are also essential, they provide improved durability under varying temperatures and resist rust, ultimately extending the life of your battery rack.

By carefully choosing each component based on its role in enhancing safety and functionality, you will ensure that your automotive battery rack is both resilient and effective for all intended purposes.

Tools Required for Construction

When starting a construction project, the right tools can make all the difference in efficiency and quality. Among the essential tools, an automotive battery rack stands out as a versatile solution for organizing batteries in various applications.

This structure not only protects the battery from physical damage but also streamlines access during installation and maintenance. By investing in a well-designed battery rack, contractors can extend the life of their components while ensuring safety and compliance with industry standards.

Another notable tool is a mobile workbench fitted with an integrated storage solution. Unlike traditional static benches, mobile options offer flexibility for projects that require fluid movement on job sites.

This adaptability allows construction teams to reduce downtime spent fetching equipment or materials, a small change that can significantly increase productivity over time.

Safety considerations during construction

When building an automotive battery rack, safety should be at the forefront of every worker’s mind. The unique nature of battery storage brings specific hazards, including chemical exposure and heavy lifting.

Proper personal protective equipment (PPE) is essential; Gloves, goggles and suitable footwear can significantly reduce the risk of injury from corrosive material or battery acid leaks.

Customization Options for Your Rack

When it comes to maximizing the performance of your automotive battery rack, customization is key. Gone are the days of one-size-fits-all solutions, today’s advancements allow enthusiasts and professionals alike to tailor their setups to specific needs.

Custom options can range from adjustable shelving heights to special compartments designed for different battery types, ensuring optimal organization and efficiency.

Incorporating unique materials can also change the game—for example, using corrosion-resistant or heat-insulating materials can significantly extend the lifespan and functionality of your rack.

Additionally, consider integrating smart technology features like a built-in monitoring system that provides real-time status updates on temperature and charge level. This not only preserves battery life but also helps predict maintenance requirements before they become serious problems.

Maintenance tips for longevity

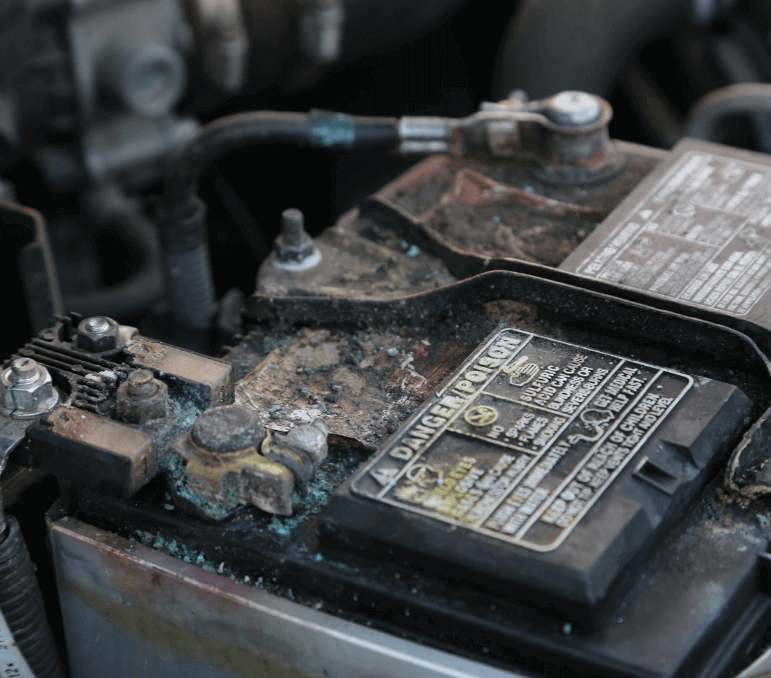

To ensure the longevity of your automotive battery rack, regular inspections are paramount. Periodically check for signs of corrosion or wear, as these can cause poor connections and inefficiency in power distribution.

Cleaning the terminals with a mixture of baking soda and water can effectively neutralize any acid build-up while ensuring a clean contact surface.

Moreover, proper insulation is crucial to maintain temperature stability. Extreme temperatures can significantly affect battery performance, so investing in thermal insulation solutions or moving the rack away from direct heat sources will increase overall lifespan.

Common Mistakes to Avoid

One of the most common mistakes when installing an automotive battery rack is to overlook the importance of proper ventilation. A well-ventilated area prevents excessive heat build-up, which can reduce battery life and performance.

By ignoring airflow considerations, you not only risk shortening your battery’s lifespan but also create a potential safety hazard due to overheating or gas build-up from charging batteries.

Another common mistake involves inadequate weight distribution on the rack. Automotive batteries can be heavy, and improper stacking can lead to structural instability or damage over time.

It is essential to ensure that the load is spread evenly across all the racks and that any racks are rated for the specific weight they are intended to hold.

Additionally, while using low-quality materials can compromise your entire setup, choosing high-quality materials made for battery storage will significantly increase safety and prolong usability while ensuring compliance with industry regulations.

Conclusion: Enjoy your DIY battery rack!

A well-made automotive battery rack not only keeps your batteries organized but also increases safety and accessibility. By spending time building a DIY battery rack, you develop a hands-on understanding of the materials involved, which can prove invaluable when it’s time for maintenance or replacement.

Plus, this can be a great opportunity to customize your setup to your specific needs, whether it’s for a hobby project, RV, or even getting a solar setup.

Don’t forget that the satisfaction you get from making something with your own hands is unbeatable. Every time you access your beautifully arranged batteries, you’ll be reminded of the effort and care you put into designing a functional space.