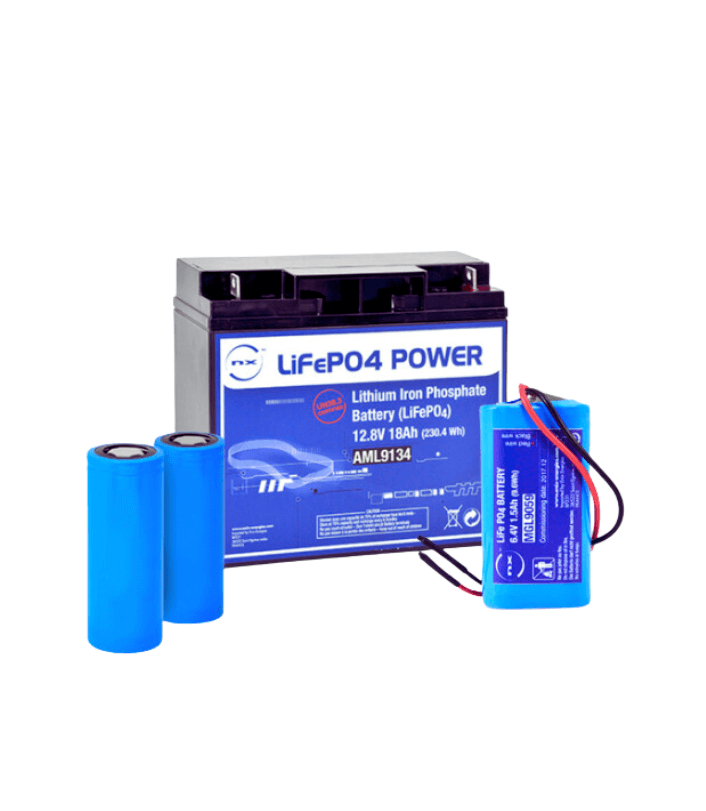

As everyone knows, lithium iron phosphate (LiFePO4) batteries are a sub-type of lithium-ion batteries that have gained popularity due to their long life, improved safety and environmental friendliness.

However, although these batteries offer significant advantages over traditional lithium-ion batteries (such as those based on nickel-cobalt-manganese or nickel-cobalt-aluminum chemistries), they also have some disadvantages that may limit their application in certain contexts. We will discuss with you the main 8 disadvantages of LiFePO4 battery which will help you a lot to know about it, let’s get started.

1. Low energy density

One of the most significant disadvantages of lithium iron phosphate (LiFePO4) batteries is their low energy density compared to other lithium-ion chemistries. Energy density refers to the amount of energy a battery has relative to its size or weight.

And while lithium-ion batteries using cobalt-based cathodes (such as nickel-cobalt-manganese, or NCM) can deliver energy densities of up to 250-300 Wh/kg, LiFePO4 batteries typically have an energy density of around 90-160 Wh/kg.

This low energy density means that for applications where space and weight are at a premium–such as electric vehicles (EVs) and portable electronics–LiFePO4 batteries may not be the most efficient choice. Moreover for electric vehicles, this translates into a shorter driving range compared to vehicles that use high-energy-density batteries.

Automakers must either increase battery size or compromise range, which can add significant weight to the vehicle and reduce overall efficiency. In aviation and portable device applications, where every gram of weight matters, this disadvantage is particularly pronounced.

2. Higher initial cost

Although lithium iron phosphate batteries have a longer lifespan than many other lithium-ion batteries, their initial cost can be high. This cost disparity is largely due to the manufacturing process and materials involved in making LiFePO4 cells. The materials used in the cathode – iron and phosphate – are less expensive than cobalt or nickel. However, the manufacturing process of LiFePO4 cells is more complex and may require more specialized equipment.

This higher up-front cost can be a barrier to adoption, especially in industries or applications where reducing capital costs is critical. Although LiFePO4’s longevity may result in lower cost-per-cycle in the long run, the higher initial cost may be a disadvantage for cost-sensitive markets such as the consumer electronics and parts of the electric vehicle industry.

3. Performance at cold temperatures

One of the main performance limitations of LiFePO4 batteries is their reduced efficiency and performance in low-temperature environments. At temperatures below 0degC (32degF), LiFePO4 batteries lose their capacity and charging efficiency significantly.

Electrochemical reactions within the battery slow down, resulting in higher internal resistance and lower power output. In extreme cold, the battery may even become unusable, requiring special warming solutions to function properly.

This limitation can be a significant disadvantage in applications where batteries are exposed to cold environments, such as in electric vehicles used in cold climates, renewable energy storage systems located outside, or off-grid power supplies in remote areas. To mitigate this problem, many systems must include heating elements or insulation, which adds to the cost and complexity of the overall system.

4. Voltage range and efficiency

LiFePO4 batteries operate at a nominal voltage of 3.2V per cell, which is lower than the 3.6-3.7V found in other lithium-ion batteries such as nickel-cobalt-manganese (NCM) or nickel-cobalt-aluminum (NCA). This lower nominal voltage can be seen as a disadvantage because it requires more cells to achieve the same overall voltage in a battery pack.

For example, to achieve the same energy capacity and output as cobalt-based lithium-ion batteries, more individual cells must be connected in series, increasing the complexity of the battery management system (BMS) and the overall battery architecture.

The overall energy efficiency may be somewhat lower in applications that rely on high-power delivery in the lower voltage range. In high-drain applications where maximizing power efficiency is critical, this lower voltage can degrade performance and lead to less optimal power consumption.

5. Low charging speed in some cases

Although lithium iron phosphate batteries are generally considered safe and durable, they have slower charging speeds than other types of lithium-ion batteries. Although they can handle fast charging better than some other chemistries without risking thermal runaway, their slow charge uptake can be seen as a disadvantage in certain applications.

For example, in electric vehicles, where fast charging is often a priority for consumers, LiFePO4 batteries can take longer to charge than high-energy-density lithium-ion alternatives. While this difference may not be huge, it can cause inconvenience, especially in fast-paced applications such as fleet vehicles or logistics operations that rely on minimal downtime.

6. Bulkier design for equivalent power output

Because LiFePO4 batteries have a lower energy density, they tend to be larger and heavier than batteries that use cobalt-based chemistry to store the same amount of energy. This increased bulk can be a significant disadvantage in applications where space and weight are limited, such as smartphones, drones, and certain types of electric vehicles.

For example, manufacturers aiming to optimize space and weight in their products may find it challenging to use LiFePO4 batteries without compromising battery life or design. In contrast, NCM or NCA batteries allow for a more compact design due to their high energy density, making them the preferred choice in portable electronics and high-performance EVs.

7. Limited availability of supply chain and infrastructure

Although LiFePO4 batteries have gained popularity in certain industries, the supply chain and manufacturing infrastructure for this type of battery is not as extensive as other lithium-ion chemistries, particularly those that use cobalt. Many battery manufacturing facilities are still optimized for making NCM or NCA batteries, which can lead to high production costs and limited availability of LiFePO4 cells.

For manufacturers that rely on established supply chains for cobalt-based lithium-ion batteries, switching to LiFePO4 may require significant changes in production processes and partnerships. This can be a disadvantage for companies looking to rapidly scale up production or adopt new battery technologies without major disruptions to their existing supply chains.

8. Not ideal for high-power applications

Although LiFePO4 batteries are adept at providing consistent power output, they are less suitable for applications that demand extremely high energy capacities, such as long-range electric vehicles, grid energy storage, and aerospace applications. The low energy density of these batteries means that they must be larger or use more power to achieve the same level of energy storage as other lithium-ion batteries, which may be impractical for some high-power applications.

As a result, companies and industries that prioritize maximum energy storage in compact spaces are more likely to use cobalt-based or nickel-based lithium-ion batteries, which offer high energy capacity despite some trade-offs in terms of safety and longevity.

Conclusion

Lithium iron phosphate (LiFePO4) batteries offer numerous advantages, including safety, longevity and environmental friendliness, making them an attractive option for many applications. However, their disadvantages, such as low power density, high initial cost, poor cold-temperature performance and bulkier design, limit their utility in some sectors, especially those requiring high power generation in a compact form.