Did you know, in terms of energy storage and power systems, batteries play an essential role, providing reliable power in a variety of applications from vehicles to renewable energy systems.

Among the most widely used battery types are absorbed glass mat (AGM) and lead-acid batteries. Despite sharing the same basic chemistry, these two battery types offer different features and benefits.

We will tell you today about the key differences, advantages, disadvantages and applications of AGM and lead-acid batteries. Because it will help you make better decisions when choosing the best power storage solution for your needs

What is a lead-acid battery?

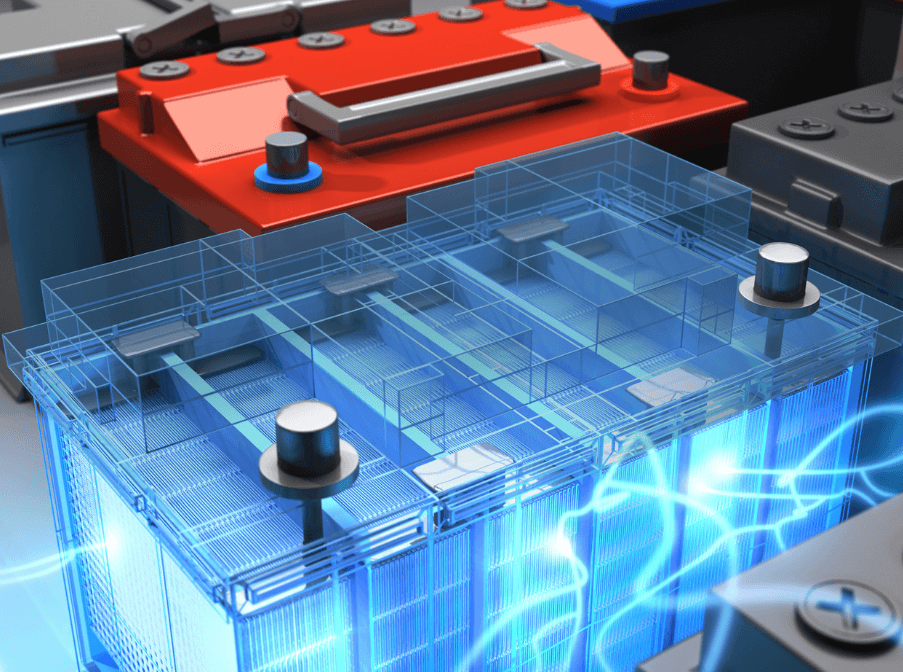

Lead-acid batteries are among the oldest and most widely used rechargeable battery technologies, invented by Gaston Plante in 1859. They consist of lead (Pb) plates immersed in a sulfuric acid (H2SO4) electrolyte, where chemical reactions between the plates and the electrolyte store and release electrical energy.

Lead-acid battery components

Positive plate (lead dioxide, PbO2): The active material in the positive electrode, which reacts with sulfuric acid during charging and discharging.

Negative plate (pure lead, Pb): The negative electrode, which reacts chemically opposite the positive plate.

Electrolyte (sulfuric acid solution): Acts as the medium through which ions move between the electrodes during battery operation.

Best features of lead-acid batteries

Capacity: Lead-acid batteries are typically rated in ampere-hours (Ah), providing energy storage capacities from a few Ah to several thousand Ah.

Voltage: The nominal voltage of a lead-acid cell is 2V, so a standard 12V battery consists of six cells connected in series.

Energy density: The energy density of lead-acid batteries is relatively low compared to modern technologies such as lithium-ion. Their weight is a significant drawback for applications requiring light batteries.

Cost: Lead-acid batteries are known to be affordable, which makes them popular for automotive and industrial applications.

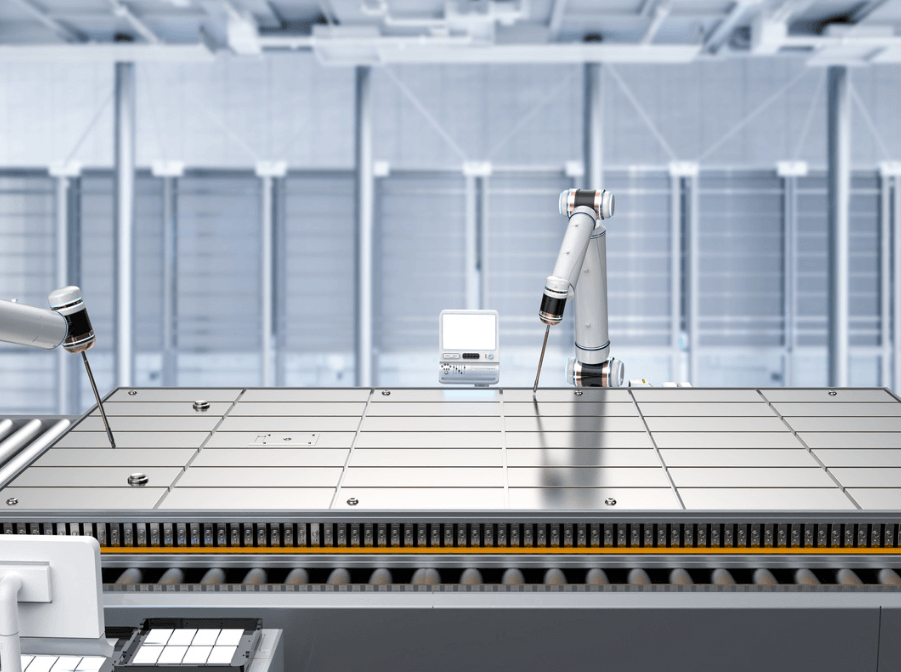

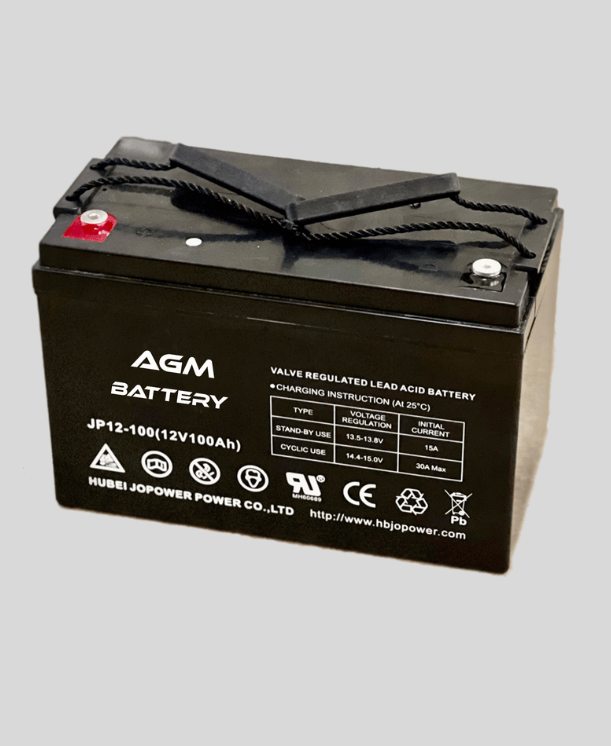

What is an AGM Battery?

Absorbed glass mat (AGM) is a type of lead-acid battery that features a highly porous fiberglass mat between the battery’s lead plates. This fiberglass mat absorbs the electrolyte, holding it in place rather than having a free-flowing liquid electrolyte. AGM batteries were originally developed in the 1980s for military aircraft and vehicles that required a more rugged, reliable power source.

How AGM batteries work

The chemical reaction in AGM batteries is similar to conventional lead-acid batteries. However, the fiberglass mat stabilizes the electrolyte, preventing leakage and allowing the battery to be sealed. The valve-controlled design allows AGM batteries to release built-up pressure, preventing damage in the event of overcharging or overheating.

AGM batteries can be charged faster, have lower internal resistance, and can handle higher power demands than traditional flooded lead-acid batteries. This makes them ideal for modern vehicles equipped with high-power electronics and start-stop systems.

Where AGM and lead-acid batteries are used

Both AGM and lead-acid batteries serve different purposes based on their unique strengths. Understanding where each battery type excels can help you decide which one is best for your specific task.

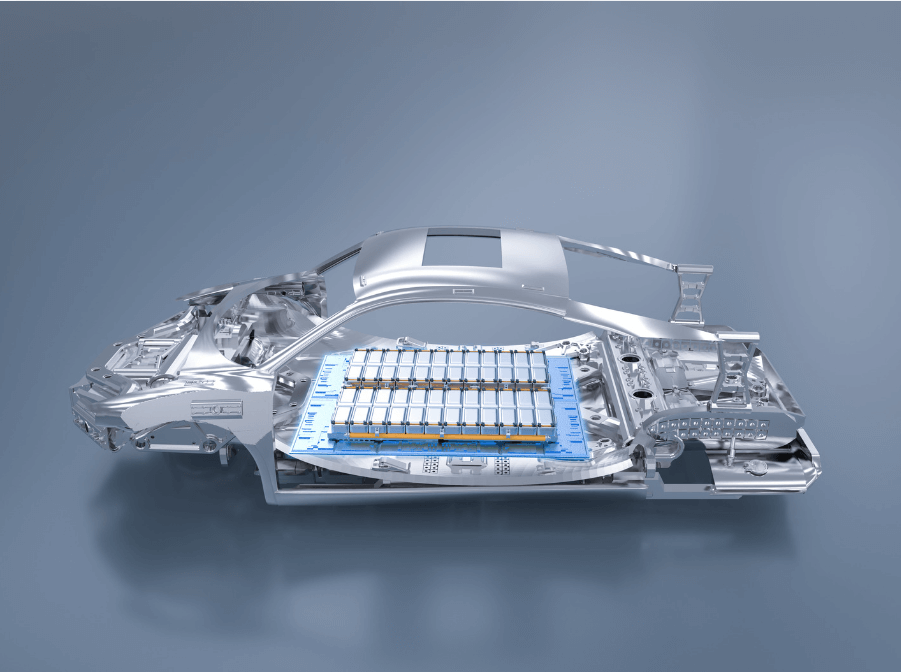

AGM battery used

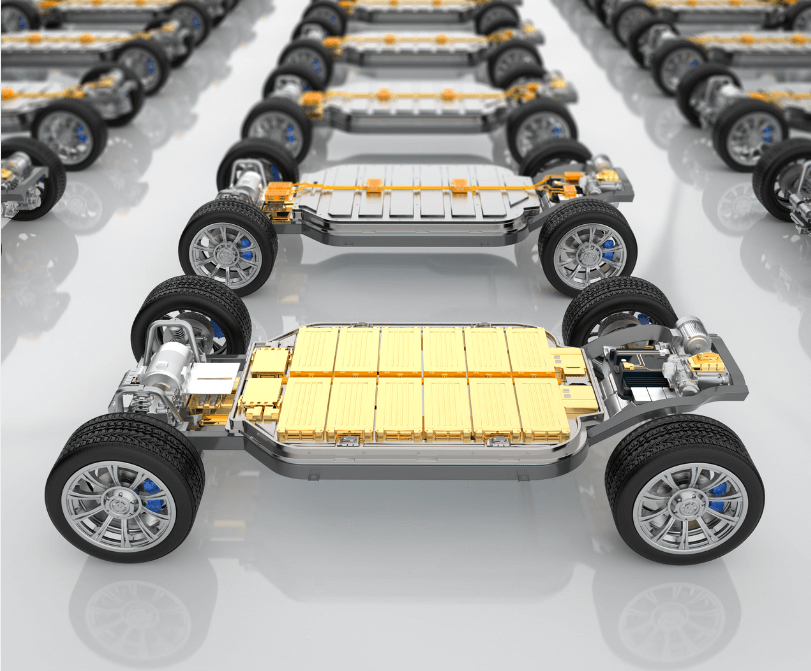

Automotive industry: AGM batteries are often used in modern cars, especially with start-stop systems, which require frequent starts and stops of the engine. They are also preferred in luxury and high-performance vehicles with high energy demands due to advanced electronics.

Marine and RV Applications: AGM batteries are extremely durable and resistant to vibration, making them ideal for use in boats, RVs and off-road vehicles. Their spill-proof design ensures safety in environments where movement and tilting often occur.

Backup Power Systems (UPS): AGM batteries are commonly used in uninterruptible power supply (UPS) systems because of their ability to provide fast, reliable power during outages. Their low self-discharge rate makes them ideal for standby power applications.

Renewable energy storage: In renewable energy systems such as solar and wind, AGM batteries provide reliable power storage and the ability to handle deep discharge cycles, which are common in renewable applications.

Motorcycles and Powersports: Due to their ability to deliver high current for cranking engines and their resistance to vibration, AGM batteries are a popular choice for motorcycles, ATVs and other powersports vehicles.

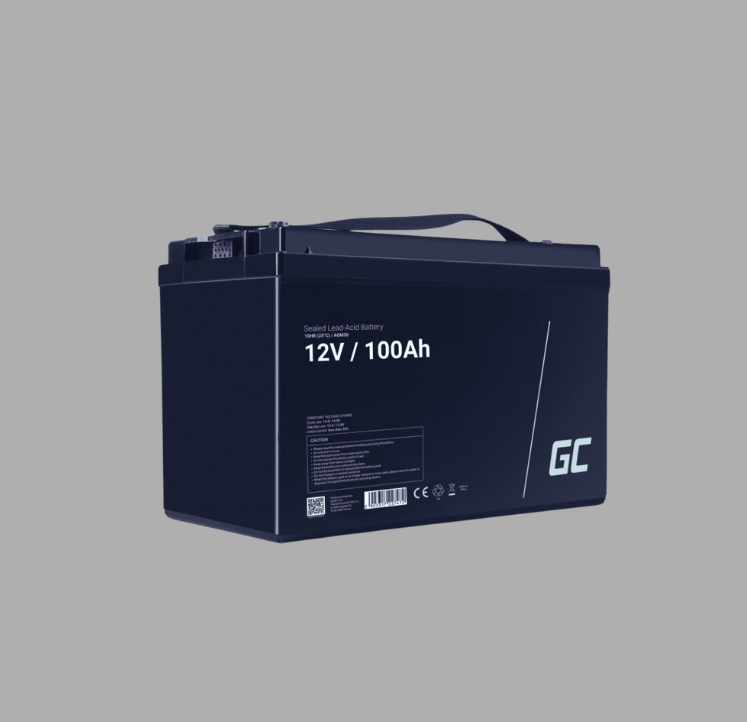

Lead-acid batteries used

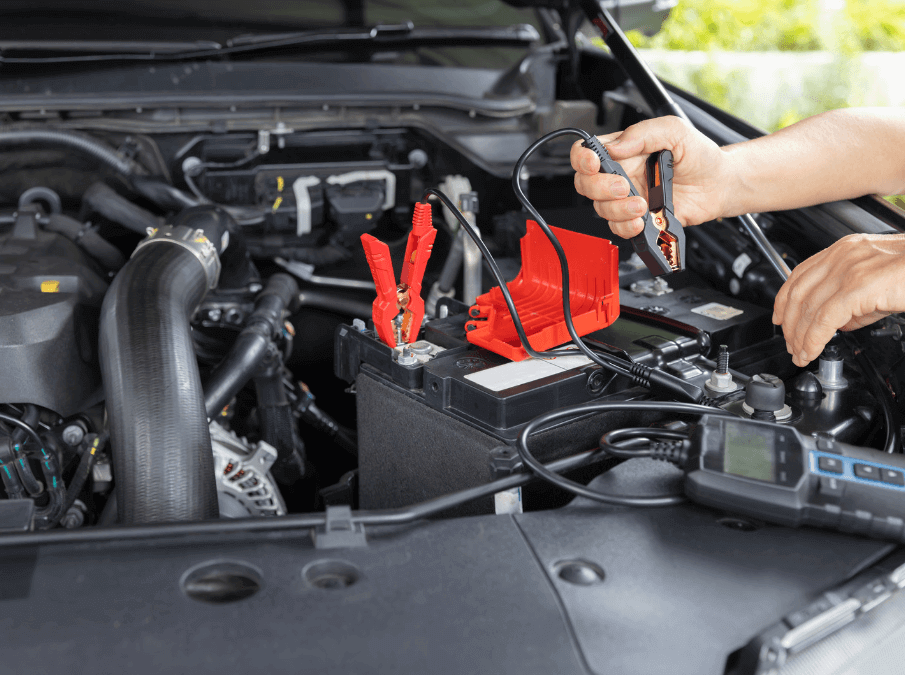

Automotive Starter Batteries: Traditional flooded lead-acid batteries are still widely used as starter batteries in conventional petrol and diesel powered vehicles. They offer reliable cranking power and are affordable for mass-market vehicles.

Off-Grid Power Systems: Flooded lead-acid batteries are used in off-grid solar and wind power systems. Although they require maintenance, their low cost makes them attractive for large energy storage setups where high upfront costs are a concern.

Forklifts and industrial vehicles: Flooded lead-acid batteries are commonly used in industrial applications, such as forklifts, due to their cost-effectiveness and reliability in high-load environments.

Standby power for telecommunication towers: In some cases, lead-acid batteries are used for backup power in telecommunication towers, although maintenance and performance in extreme temperatures can be a concern.

Maintenance

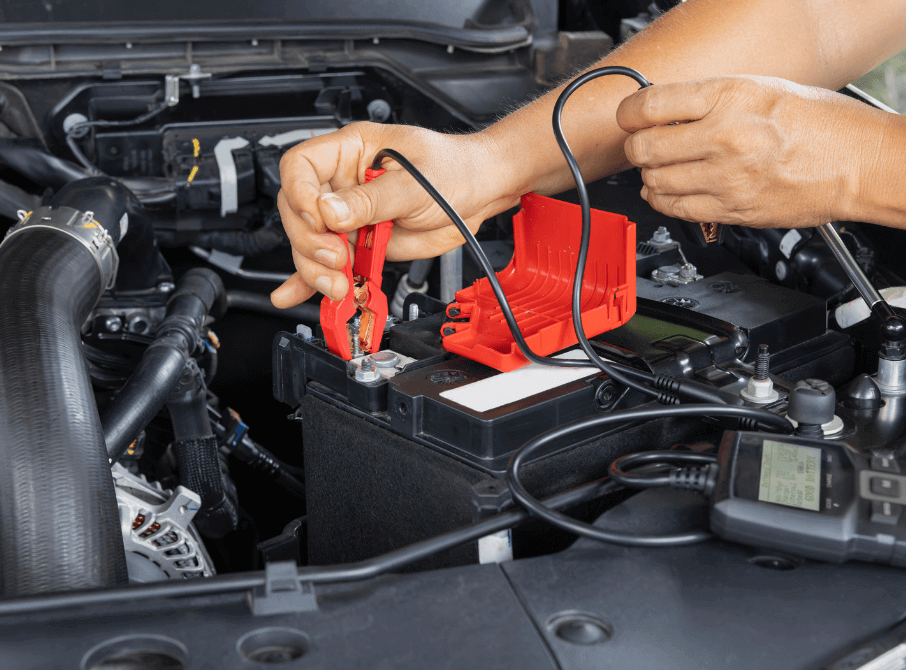

AGM Battery: Maintenance-free, as the electrolyte is absorbed in a fiberglass mat and does not require topping up with water.

Lead-Acid Battery: Requires regular maintenance, such as checking and refilling water levels due to the evaporation of electrolyte.

Design and Structure

AGM Battery: Sealed design with an Absorbed Glass Mat that immobilizes the electrolyte, making it spill-proof and safe to use in any position.

Lead-Acid Battery: Flooded design with liquid electrolyte, which can spill if the battery is tilted or damaged.

Charging Speed

AGM Battery: Faster charging due to lower internal resistance, making it more efficient for high-drain applications and frequent use.

Lead-Acid Battery: Slower to charge due to higher internal resistance and less efficient in high-power demand scenarios.

Durability and Vibration Resistance

AGM Battery: More resistant to vibrations and shocks, making it ideal for vehicles, off-road equipment, and marine applications.

Lead-Acid Battery: More prone to damage from vibrations or shocks, and requires careful handling in rough environments.

Lifespan

AGM Battery: Longer lifespan, especially under deep discharge conditions, and can last up to 5 years longer than flooded lead-acid batteries.

Lead-Acid Battery: Shorter lifespan, particularly when subjected to deep discharges or poor maintenance.

Depth of Discharge (DoD)

AGM Battery: Can tolerate deeper discharges (up to 80% DoD) without significant loss of performance or lifespan.

Lead-Acid Battery: Should typically not be discharged below 50% DoD, as deeper discharges can greatly reduce its lifespan.

Self-Discharge Rate

AGM Battery: Has a lower self-discharge rate, meaning it can hold its charge for longer periods when not in use.

Lead-Acid Battery: Has a higher self-discharge rate and requires more frequent recharging if left unused for extended periods.

Temperature Performance

AGM Battery: Performs better in extreme temperatures, both hot and cold, making it more reliable in harsh environments.

Lead-Acid Battery: More sensitive to extreme temperatures, which can degrade performance, especially in cold weather.

Cost

AGM Battery: More expensive upfront due to its advanced design and superior performance.

Lead-Acid Battery: More affordable, making it a cost-effective choice for applications where performance is not as critical.

Safety and Environmental Impact

AGM Battery: Sealed, non-spill design makes it safer to handle and less prone to leaks or corrosion.

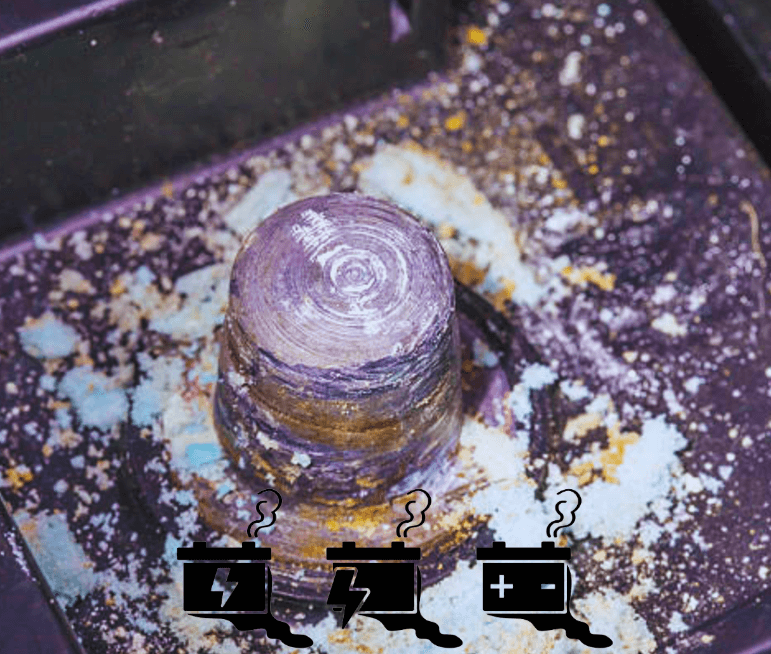

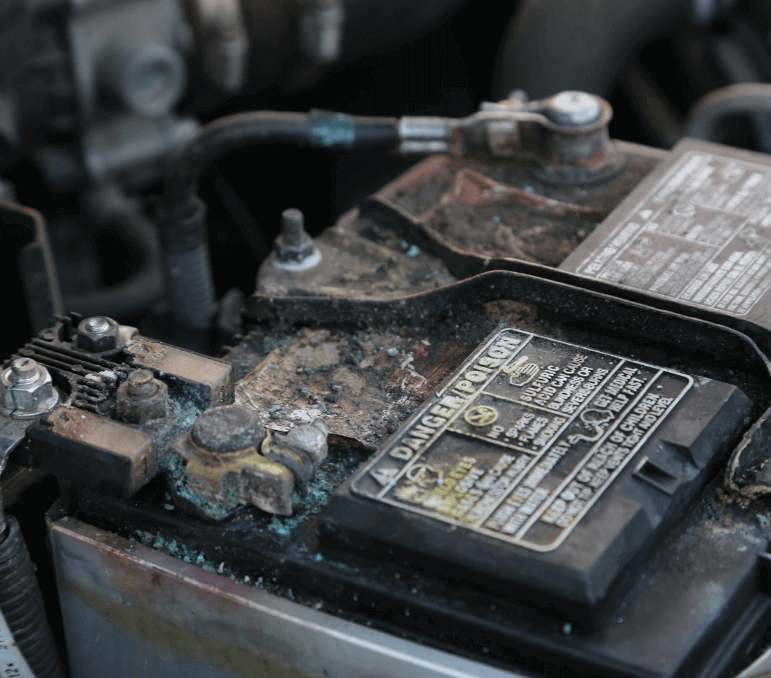

Lead-Acid Battery: Prone to leaks and spills if handled improperly, which can lead to safety hazards and environmental concerns.

Advantages and Disadvantages of AGM and Lead-Acid Batteries

Advantages of AGM Batteries

Maintenance-Free: AGM batteries do not require periodic watering, making them ideal for low-maintenance applications.

High Power Output: Due to their low internal resistance, AGM batteries can deliver high bursts of power, making them suitable for applications like automotive starting and power-hungry devices.

Vibration Resistant: AGM’s sealed and compact design makes it resistant to shock and vibration, allowing use in rugged conditions.

Disadvantages of AGM Batteries

Higher Cost: AGM batteries are generally more expensive than traditional flooded lead-acid batteries due to their advanced design and improved performance.

Sensitive to Overcharging: While AGM batteries are more durable in general, they are more susceptible to damage from overcharging. Proper charge regulation is necessary to prevent degradation.

Heavy: Despite offering better performance, AGM batteries are still heavy due to the lead-based chemistry, which can be a concern in weight-sensitive applications.

Advantages of Lead-Acid Batteries

Cost-Effective: Lead-acid batteries are generally cheaper than AGM batteries, making them the preferred option in applications where cost is a major concern.

Proven Technology: Lead-acid batteries have been used for over a century and are well-understood. Their simplicity and proven reliability make them a popular choice for a wide range of applications.

Recyclability: Lead-acid batteries are highly recyclable, with over 90% of their materials, including lead and sulfuric acid, being recoverable, making them environmentally friendly compared to other battery types.

Disadvantages of Lead-Acid Batteries

Requires Maintenance: Flooded lead-acid batteries require regular maintenance, including checking electrolyte levels and adding distilled water, which can be a disadvantage in applications where maintenance is difficult or impractical.

Lower Lifespan: Lead-acid batteries generally have a shorter lifespan compared to AGM batteries, especially in applications where deep discharges are common.

Prone to Spillage and Leakage: Flooded lead-acid batteries are not sealed and can leak if tipped over, which poses a safety hazard.

Which battery type should you choose?

Choosing between AGM and traditional lead-acid batteries depends on the specific needs and limitations of your application. Here are a few things that might make one type more suitable than the other:

Choose AGM batteries if:

- You need a maintenance-free, spill-proof solution.

- High performance, fast charging, and deep-cycle capability are essential.

- Vibration resistance is important (eg, in marine or off-road applications).

- You need reliable performance in extreme temperatures.

Choose flooded lead-acid batteries if:

- Budget is a primary concern and you need a cost-effective solution.

- Maintenance is not a problem and you are comfortable checking the electrolyte level regularly.

- You are using the battery for automotive starting for standard applications where deep-cycle capability is not required

We think these differences explain how AGM batteries generally offer better performance, durability and safety, but at a higher cost than traditional lead-acid batteries. Depending on your specific needs, I think these factors can guide your decision in choosing the right battery type.