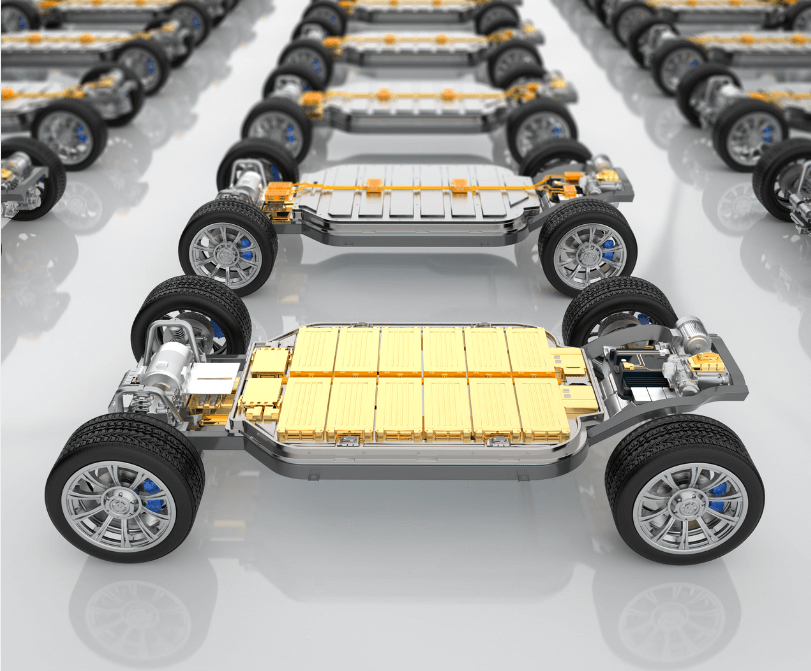

In the modern era, where sustainability and environmental responsibility are becoming increasingly important, one area in particular that has received considerable attention is battery recycling. Batteries are ubiquitous in modern life, powering everything from smartphones and laptops to electric vehicles (EVs) and renewable energy systems.

However, with the rapid growth in battery usage comes the important issue of responsibly handling spent or discarded batteries. This is where battery recycling systems play a vital role in ensuring that used batteries are recycled properly.

This article will discuss the importance of battery recycling systems, the types of batteries that need to be recycled, and the processes involved, the technologies used, and the challenges faced by the recycling industry Let’s get started.

Introduction to Battery Recycling

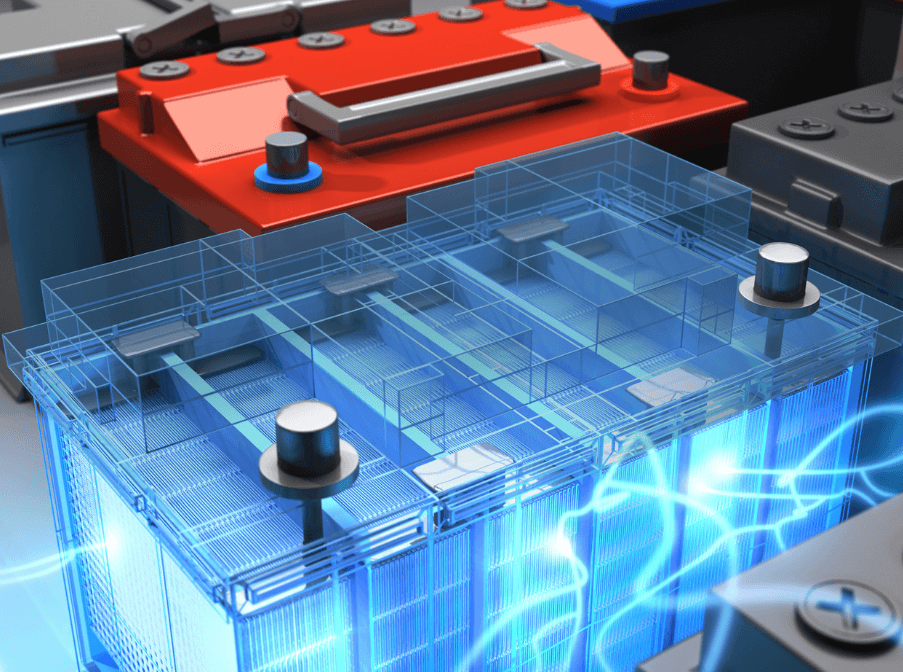

Battery recycling refers to the process of collecting and processing used or discarded batteries to extract valuable materials and prevent harmful environmental impacts. Batteries contain a variety of materials such as lead, lithium, cobalt, and nickel that can be harmful if not disposed of properly. Recycling systems aim to recover these materials, reduce landfill waste, and mitigate the environmental footprint associated with raw material mining.

In the past, many consumers and businesses were unaware of the importance of recycling batteries. However, with increasing awareness of climate change, the impact of e-waste, and the shift toward electric mobility, battery recycling systems have become an essential part of the global waste management infrastructure.

Why battery recycling is important

Battery recycling provides multiple environmental, economic and social benefits. Some of the primary reasons why battery recycling is important include:

Environmental protection: Batteries contain toxic materials such as lead, mercury and cadmium, which can cause soil, water and air pollution if not disposed of properly. Recycling prevents these harmful materials from being released into the environment.

Resource conservation: Batteries contain valuable raw materials, including rare earth metals such as cobalt, lithium and nickel, as well as more common materials such as copper and steel. Recyclers allow these materials to be recovered and reused in the production of new batteries or other products.

Waste reduction: The increasing reliance on portable electronics and electric vehicles has led to higher battery costs, which could otherwise contribute to the growth of e-waste. Battery recycling reduces the amount of waste sent to landfills, helping to conserve valuable landfill space and reduce waste.

Economic opportunity: Recovering valuable metals from spent batteries offers a profitable business opportunity. As demand for these metals continues to grow, battery recycling can help businesses tap into a growing market by reducing their reliance on virgin raw materials.

Types of Batteries and Their Recycling Requirements

Not all batteries are the same, and recycling processes vary depending on the type of battery. Check out the most common types of batteries and their specific recycling requirements below:

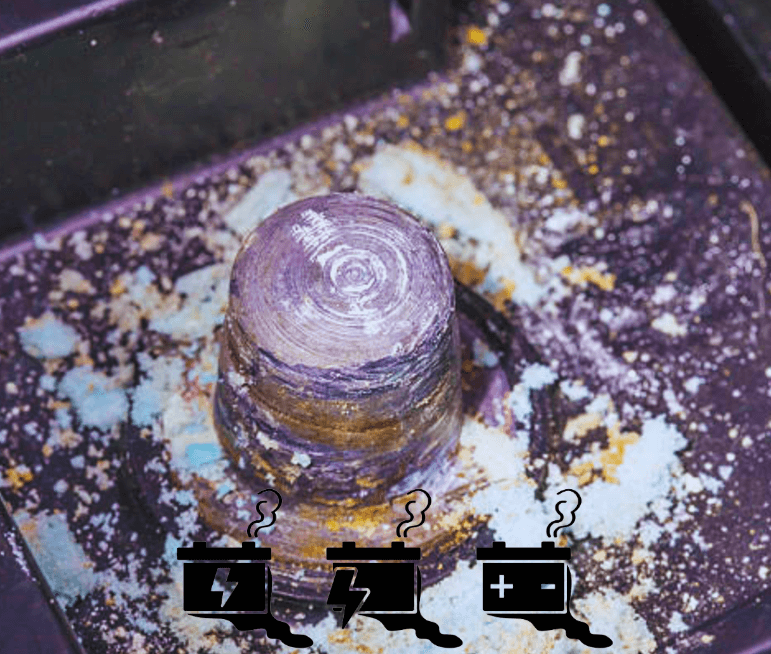

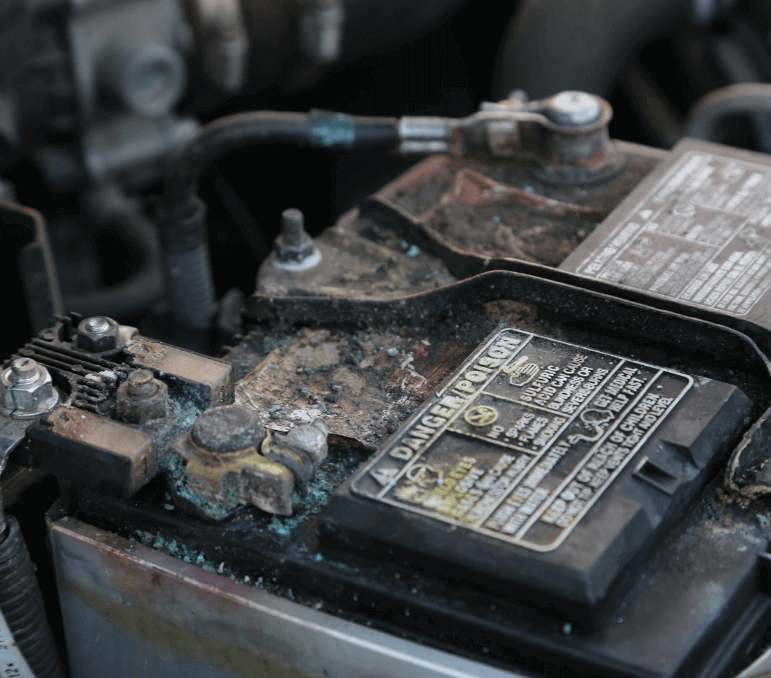

Lead-acid batteries

Lead-acid batteries, commonly used in vehicles and backup power systems, are one of the oldest and most widely recycled battery types. They are composed of lead plates and sulfuric acid, both of which can be harmful if not handled properly. Recycling lead-acid batteries involves breaking down the battery into its components, neutralizing the acid, and recovering the lead for reuse.

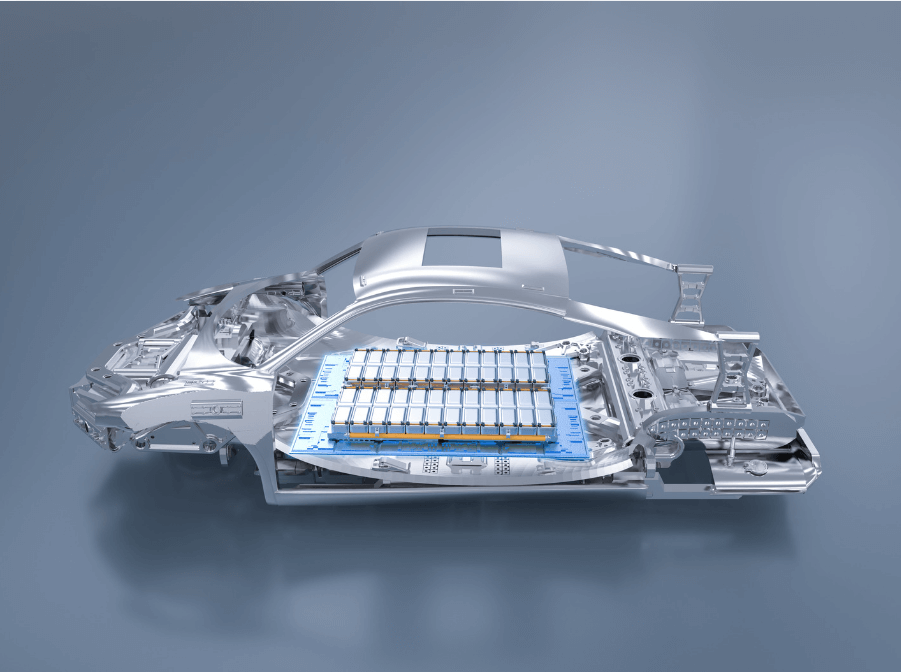

Lithium-ion batteries

Lithium-ion (Li-ion) batteries are widely used in portable electronics, electric vehicles, and renewable energy storage systems. These batteries are more complex than lead-acid batteries and contain valuable elements such as lithium, cobalt, and nickel. Recycling lithium-ion batteries involves discharging, disassembling, and then extracting the materials using a variety of methods, including mechanical shredding and hydrometallurgical processes.

Nickel-cadmium (Ni-Cd) batteries

Nickel-cadmium batteries, although less commonly used today, are still found in some power tools, cameras, and other devices. These batteries contain toxic cadmium, which can pose an environmental hazard if not recycled properly. The nickel and cadmium are recovered through a hydrometallurgical process, and the batteries are dismantled to separate these materials.

Alkaline batteries

Alkaline batteries, often found in household items such as remote controls and toys, are typically non-rechargeable. Although they are less hazardous than other types of batteries, they still contain small amounts of mercury, zinc, and manganese. Recycling alkaline batteries focuses on recovering these metals and preventing landfill contamination.

How the Battery Recycling Process Is Done

Battery recycling involves several steps from collection to final processing. The primary steps in the recycling process are as follows:

Collection and Sorting

The first step in recycling is to collect used batteries. This is usually done through drop-off locations at retail stores, recycling centers, or collection events. Once the batteries are collected, they are sorted by type, as different batteries require different processing methods.

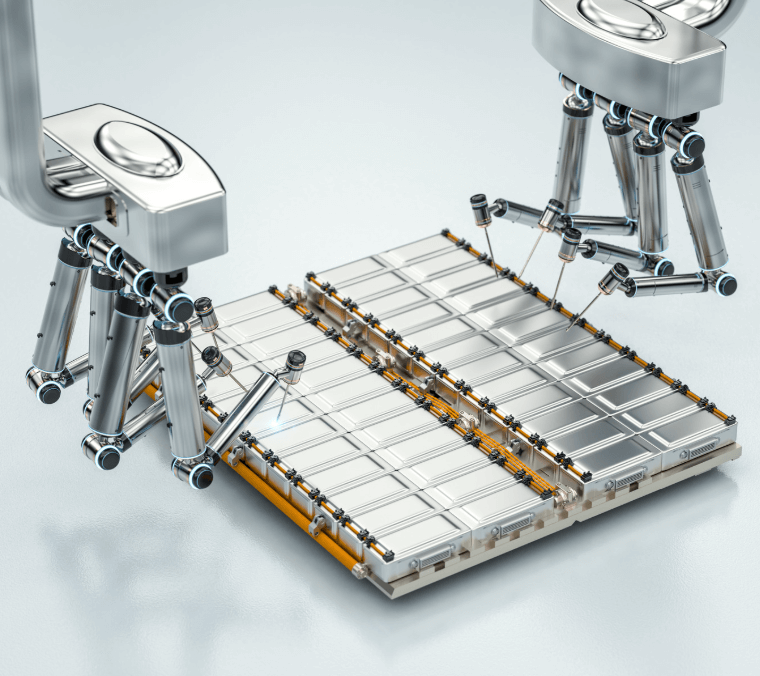

Discharge and Disassembly

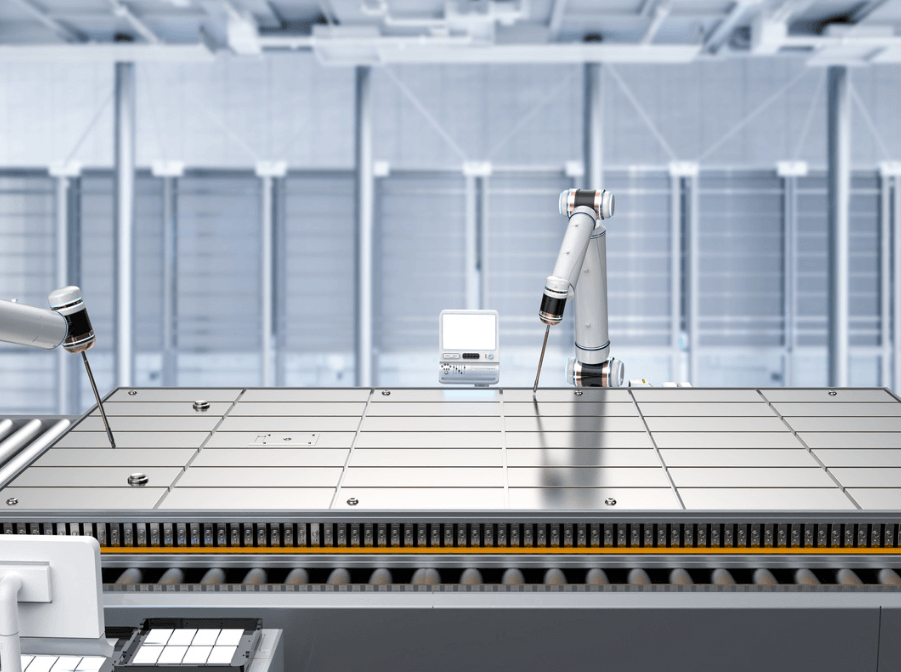

Before recycling, batteries must be safely discharged to prevent any potential hazards during handling. The next step involves dismantling the batteries to remove hazardous components such as acid or lithium. This is often done manually or with automated machines.

Material Separation

Once the batteries have been disassembled, the materials must be separated. This can be done through mechanical processes, such as shredding, or chemical processes, such as hydrometallurgical techniques, where solvents are used to extract certain metals.

Final Processing and Refining

After the materials are separated, they are sent through a refining process to recover valuable metals such as cobalt, lithium, nickel, and lead. These metals are then purified and can be used to make new batteries or other products.

What technologies are used in battery recycling systems?

Battery recycling is a growing field that incorporates a variety of technologies to improve efficiency, reduce costs, and maximize the recovery of valuable materials. The primary technologies used in battery recycling include:

Mechanical Recycling

Mechanical recycling involves physically breaking batteries into smaller pieces using shredders, crushers, and separators. This method is primarily used for batteries such as lead-acid and nickel-cadmium, as it is effective in recovering large amounts of lead and other metals.

Pyrometallurgical recycling

Pyrometallurgical recycling uses high temperatures to melt and refine the metals in batteries. This method is effective for recovering metals such as copper, gold, and silver. However, it can be energy-intensive and produces emissions, which is why it is usually used for certain types of batteries.

Hydrometallurgical recycling

Hydrometallurgical recycling uses aqueous chemical solutions to extract valuable metals from batteries. This method is usually used for lithium-ion batteries, as it allows for the selective extraction of lithium, cobalt, and other rare earth metals. It is more energy-efficient and environmentally friendly than the pyrometallurgical process.

Does battery recycling face any challenges?

Yes, despite its many benefits, battery recycling faces several challenges:

Complexity of battery types: Different types of batteries require different recycling processes, and as new battery technologies emerge, recycling systems must adapt to handle these changes.

Cost of recycling: Recycling batteries can be expensive, especially for advanced technologies like lithium-ion. The costs of collection, sorting, and processing can make recycling less economically viable without proper incentives.

Limited infrastructure: While battery recycling programs are growing, they are not yet universally available. Expanding recycling infrastructure, especially in developing regions, is critical to improving recycling rates worldwide.

Toxicity and hazards: Some batteries, especially old or damaged batteries, can pose significant risks during the recycling process. Proper safety measures and regulations are essential to ensure that workers and the environment are protected.

The answer is, the amount of a battery that can be recycled depends on the type of battery and the technology used in the recycling process. However, for your convenience, we have provided a sample of the recycling rates of some popular batteries below.

1. Lead-Acid Batteries

Recycling Rate: 95-98%

Lead-acid batteries are the most successfully recycled type of battery. Most of the components, including lead, sulfuric acid, and plastic casings, are recovered and reused.

Lead is purified and reused in the production of new lead-acid batteries.

Sulfuric acid is neutralized and converted into water or used to produce sodium sulfate, which can be used in detergents or glass manufacturing.

The plastic casing is typically cleaned and reused in the production of new battery cases.

Lead-acid batteries have one of the highest recycling rates because of the established recycling infrastructure and the value of the materials involved.

2. Lithium-Ion Batteries

Recycling Rate: 50-60% (current rate, with potential for improvement)

Lithium-ion batteries, used in consumer electronics and electric vehicles, can have a recovery rate of 50-60% for their materials. The materials typically recovered include:

- Lithium

- Cobalt

- Nickel

- Copper

- Graphite

- Aluminum

The recycling process for lithium-ion batteries is more complex compared to lead-acid batteries because they contain a mix of materials that need to be carefully separated. The recovery rate is expected to improve with advancements in recycling technology, such as direct recycling methods and hydrometallurgical processes.

3. Nickel-Cadmium (Ni-Cd) Batteries

Recycling Rate: 75-90%

Nickel-cadmium batteries contain valuable metals like nickel and cadmium, which can be efficiently recovered.

Nickel is usually recovered and reused in new batteries or other industrial applications.

Cadmium, although toxic, is recovered and safely disposed of or reused in other products.

Steel and other metals from the battery casing are also recycled.

While cadmium recovery is essential due to its toxic nature, the recycling rate for Ni-Cd batteries can be quite high, especially in regions with robust recycling programs.

4. Alkaline Batteries

Recycling Rate: Approximately 5-10% (current rate, depending on the process)

Alkaline batteries are more difficult to recycle due to their simple construction, but the following materials can still be recovered:

- Zinc

- Manganese dioxide

- Steel

Alkaline batteries are often not recycled in large quantities because of the low recovery value and the fact that they are less hazardous than other battery types. However, some recycling facilities do recover small amounts of zinc and manganese, which can be reused.

5. Zinc-Carbon Batteries

Recycling Rate: Approx. 50% (though low compared to others)

Zinc-carbon batteries are similar to alkaline batteries, and their recycling rate is modest. Zinc is recovered and can be reused, while other materials like steel and manganese are also recycled.

In short, a significant portion of a battery can typically be recycled, with lead-acid and nickel-based batteries showing the highest recyclability.

Conclusion

Battery recycling systems are not only integral to recovering valuable materials but also to reducing waste, protecting the environment, and supporting future green technologies. The global shift towards sustainability relies on innovative solutions like battery recycling, and by embracing these practices, we can pave the way for a cleaner, more efficient world.